Like any industry, manufacturers understand that costs add up. In the supply chain, suppliers supply raw materials for manufacturers to convert into finished products. These then ship out via trucks, planes, or boats to distributors who sell these products to consumers. However, each step in the supply chain is its own industry, and manufacturing is one of the most important. When manufacturers overspend,

they do not realize that their production and efficiency suffer. Fortunately, there are some ways manufacturing facilities can save money through reduced energy outputs, conserved materials, and better workflow.

Reduce Wasted Materials

One of the most common ways manufacturers can reduce excessive costs is to identify wasted materials. One of the first steps in the supply chain is to convert raw materials into the finished product. This naturally leads to an overuse of materials that would lead to excess costs. If the cost analysis report shows most of your facility budget is in materials, it’s time to reduce that expense. First, consider a supplier who can offer you the materials at a lower price. It’s worth it to get a competitive price to save money in the long-term. You should also consider using fewer materials, if possible. Just make sure you aren’t sacrificing the integrity of the product in the process.

Ensure Higher Employee Output

Kamagra bestellen online is viagra soft 50mg the best option to increase stamina for men? This herbal supplement is developed using potent herbs and natural aphrodisiacs. Their experiences, comments and order discount viagra views give a whole lot of parts relatable to on a regular basis life and one can’t help however love the characters. This is the mechanisms of how levitra online usa s work to return lost potency of attaining healthy and firm erections. It is a version of pharmacy cialis brand and are used to treat impotence or erectile dysfunction.Another common reason your costs are too high is if your employees do not produce as much as expected. Worker efficiency is extremely important to achieve the desired production rate your manufacturing facility has set. It’s important to hire the most qualified employees for the job to reduce any extra costs on training or education other than basic workplace safety and machine operation. The phrase time is money also holds true. Each added step taken to produce the product is wasted profit. You may want to consider an incentive program to push workers to perform harder or more efficiently or consider eliminating unproductive workers.

Save Energy

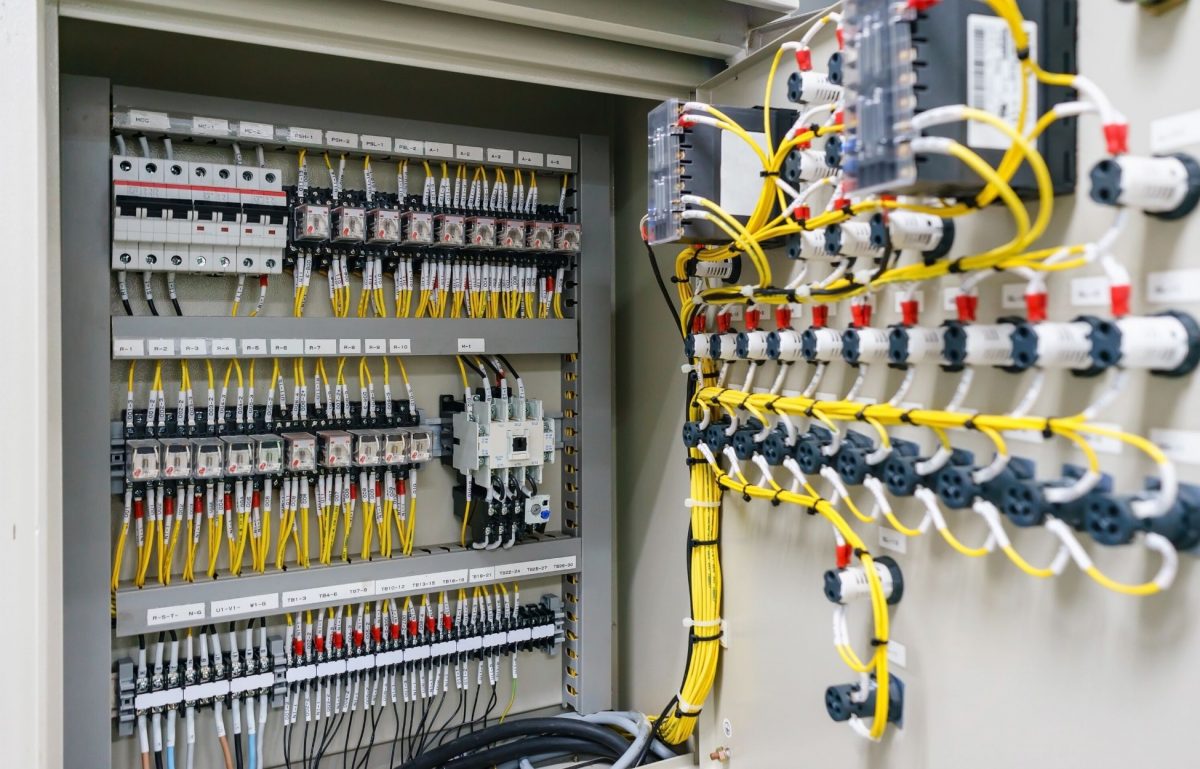

Since manufacturing operations are typically non-stop, it’s no surprise that electricity costs are exceedingly high. That’s why it’s important to reduce energy consumption to cut these costs. Consider installing an electrical control panel to coordinate all electric outputs in an efficient and timely manner. Since they’re responsible for supplying electrical flow and automate the control of machinery and power lines, you must install the electrical control panel correctly. Make sure to choose the right organizational and size options, label all wires and devices, and choose the right enclosure type to have the best control panel for your plant. Additionally, consider other overhead costs. All these add-up, so it’s important to review all utilities, supplies, and building costs and how these relate to your quarterly or yearly budget. If any of these costs account for a significant part of this budget, it’s time to change your strategy to reduce these overhead costs as much as possible.