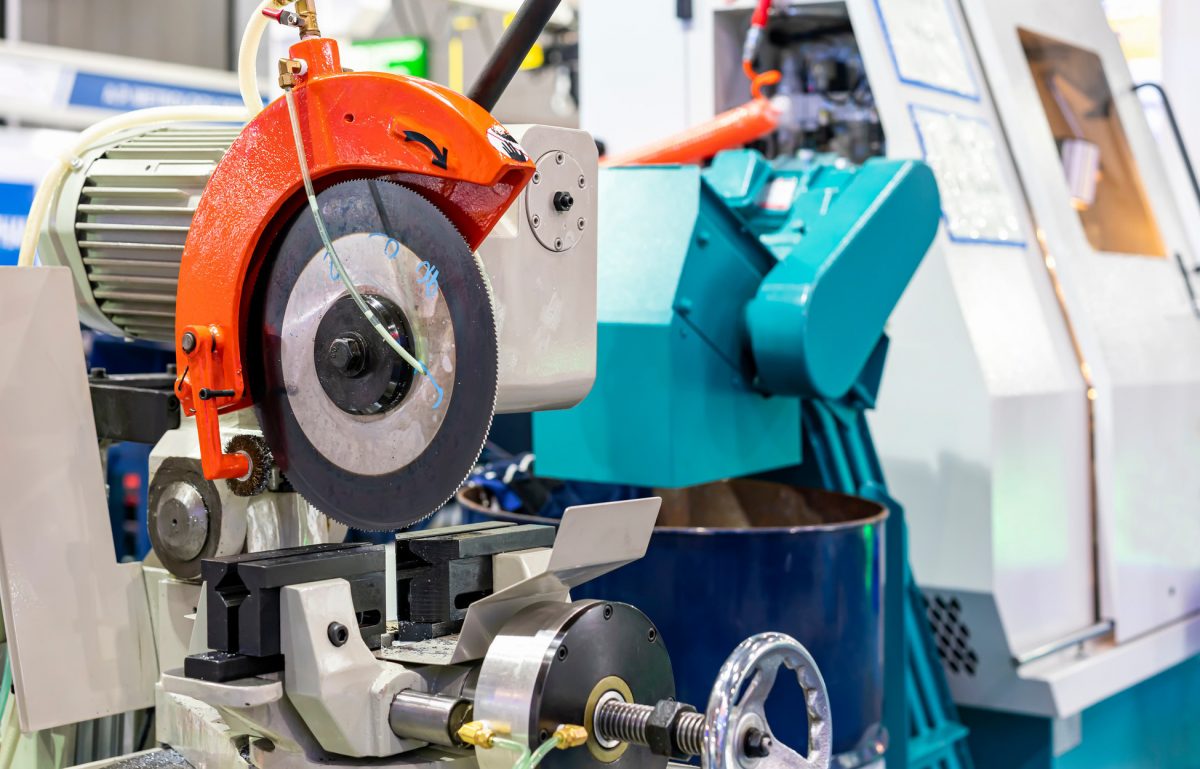

Industrial cold saws are foundational tools for precision cutting in metalworking. And regardless of your title or project demands, choosing the right cold saw can make or break your workflow. With so many options available, how do you determine the right one for your needs? We’re taking you through what you need to know before investing in an industrial cold saw, ensuring you make an informed, wise financial decision.

Key Features To Look for Before Investing

Durability, precision, and ease of operation should top your checklist when evaluating an industrial cold saw. Look for models with high-quality, carbide-tipped blades—they are long-lasting and deliver cleaner cuts on various materials.

Additionally, check for adjustable cutting angles and clamp systems, as they allow for greater flexibility across projects. The motor’s horsepower is another critical aspect, as a more powerful motor can handle tougher metals without stalling or damaging the blade.

The Importance of Safety Features

Industrial cold saws are high-powered tools that pose risks if not operated correctly. Investing in a model with comprehensive safety features is critical. Make sure the saw includes a blade guard to minimize contact with the blade, emergency stop controls for immediate shutdown, and a secure clamping system to keep the material steady during operation.

Some advanced models feature overload protection sensors to prevent overheating or tool failure. By prioritizing safety features, you protect the operator and the longevity of the equipment. Always prioritize safety as a nonnegotiable aspect of your investment.

Maintenance Tips To Extend Your Cold Saw’s Lifespan

Investing in an industrial cold saw is just the beginning. Keeping it in optimal condition requires regular maintenance. Make sure the blades are sharpened or replaced when dull and always clean the machine to remove metal debris that could damage its components. Lubricating moving parts and aligning clamps are essential for smooth operation.

Proactive maintenance will extend the machine’s lifespan and improve cutting performance. For detailed steps, read through this complete guide to maintaining your cold saw to ensure you’re equipped to get the most out of your investment.

Budget Considerations for an Industrial Cold Saw

Cold saws can range from a few thousand to tens of thousands of dollars depending on their features, size, and type. It’s important to balance quality with budget. Don’t just go for the cheapest option—it likely won’t offer the performance or durability you require. Instead, understand your workflow and choose a tool that delivers value over time.

Also, factor in additional costs for blades, ongoing maintenance, and potential upgrades. Taking a cost-of-ownership approach will give you a clear picture of long-term expenses beyond the initial purchase.

Choosing the right industrial cold saw requires thoughtful consideration of your needs, budget, and safety. With the right investment, you’ll boost efficiency and improve the quality of your output.