The need for rapid innovation and quick adaptation has become more critical than ever. Companies continuously seek ways to reduce time-to-market while ensuring their products meet the highest quality standards.

One effective approach to achieving these goals is collaborating with a reputable prototype manufacturer. This partnership accelerates the transition from conceptual designs to tangible products and allows for the early detection and correction of potential design flaws. The benefits of working with a prototype manufacturer will set the stage for successful product launches and long-term growth.

Accelerated Product Development

One of the primary benefits of collaborating with a prototype manufacturer is the acceleration of product development timelines. These experts have the tools and expertise to bring a concept to life quickly, allowing for constant refinement and iteration. By reducing the time taken from design to prototype, businesses can swiftly respond to market demands and customer feedback.

Cost Efficiency

Cost efficiency is another compelling reason to engage with a prototype manufacturer. Traditional manufacturing processes often require significant upfront investments in machinery and tooling. Prototype manufacturers typically offer flexible solutions with lower initial costs. This approach allows business leaders to refine their designs without incurring the high expenses of setting up full-scale production. This reduces the risk of committing significant resources to an unproven product.

Flexible Manufacturing Methods

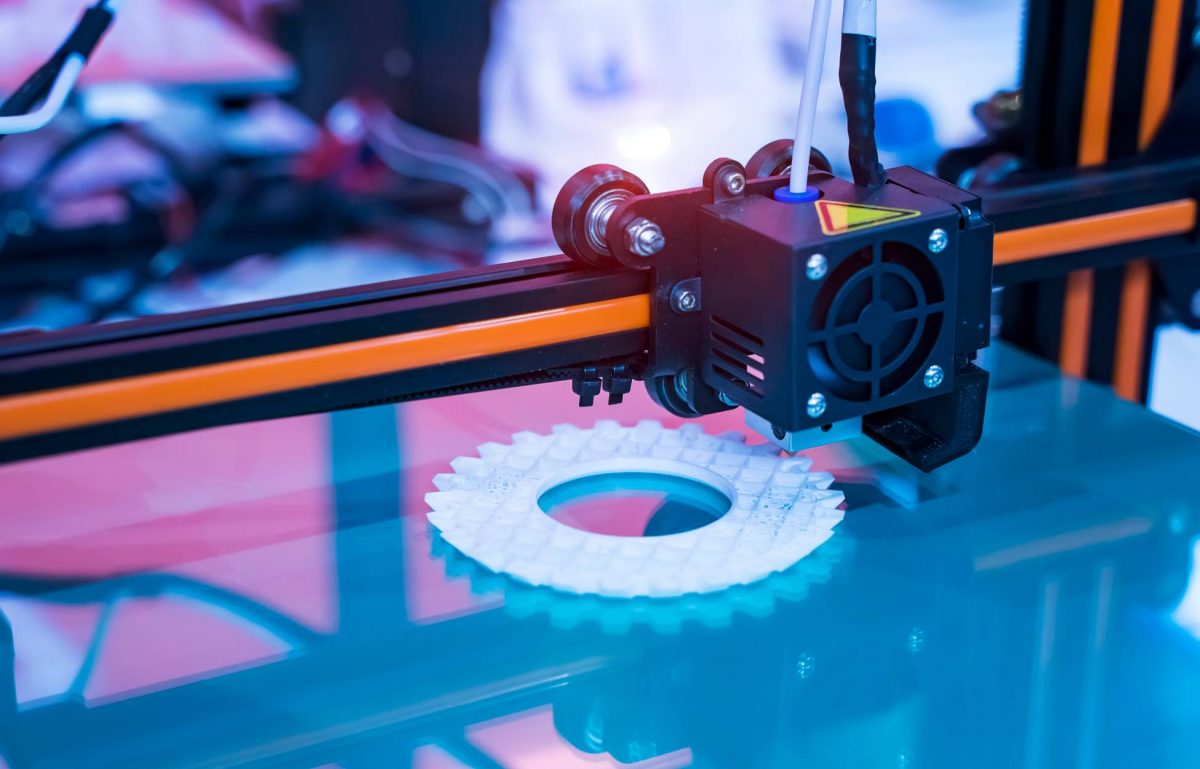

Prototype manufacturers offer a range of flexible manufacturing methods, including CNC machining, 3D printing, and reaction injection molding. They can help you understand when to use reaction injection molding to impact the final product’s durability and cost-effectiveness. This flexibility allows business owners to choose the most appropriate technique for their products, providing tailored solutions that meet design requirements and production volumes.

Enhanced Creativity and Innovation

Working with prototype manufacturers empowers businesses to be more creative and innovative. With fewer constraints on the manufacturing process, designers can experiment with unconventional ideas and materials. Prototype specialists often have experience in various industries, bringing fresh perspectives and suggestions to the table, which can enhance the design and functionality of the product.

Improved Product Testing

Prototypes are crucial for validating a product’s design, functionality, and market readiness. Engaging with a prototype manufacturer facilitates testing and evaluation. Through this process, they can identify and address potential design flaws before full-scale production. Rigorous testing guarantees that the finished product meets quality standards and customer expectations.

These benefits of working with a prototype manufacturer provide companies with a strategic advantage in product development. With these capabilities, business leaders are better positioned to succeed in competitive markets.