In the world of manufacturing and metalworking, centerless grinding stands out as a key process. Centerless grinding has many applications and advantages, two of the big advantages being precision and efficiency. But how do manufacturers ensure they achieve these traits? Below, we discuss tips for precision and efficiency in centerless grinding.

Understand Your Material

The characteristics of the material you’re working with significantly affect your grinding strategy. Materials vary in properties such as hardness, thermal conductivity, and resistance to wear, which can all influence how they should be ground. Knowing your material well allows for better selection of grinding wheels, speed adjustments, and feed rates that are optimal for the material in question. This knowledge not only leads to more precise outcomes but also prevents damage to the material and extends the life of your grinding equipment.

Choose the Right Grinding Wheel

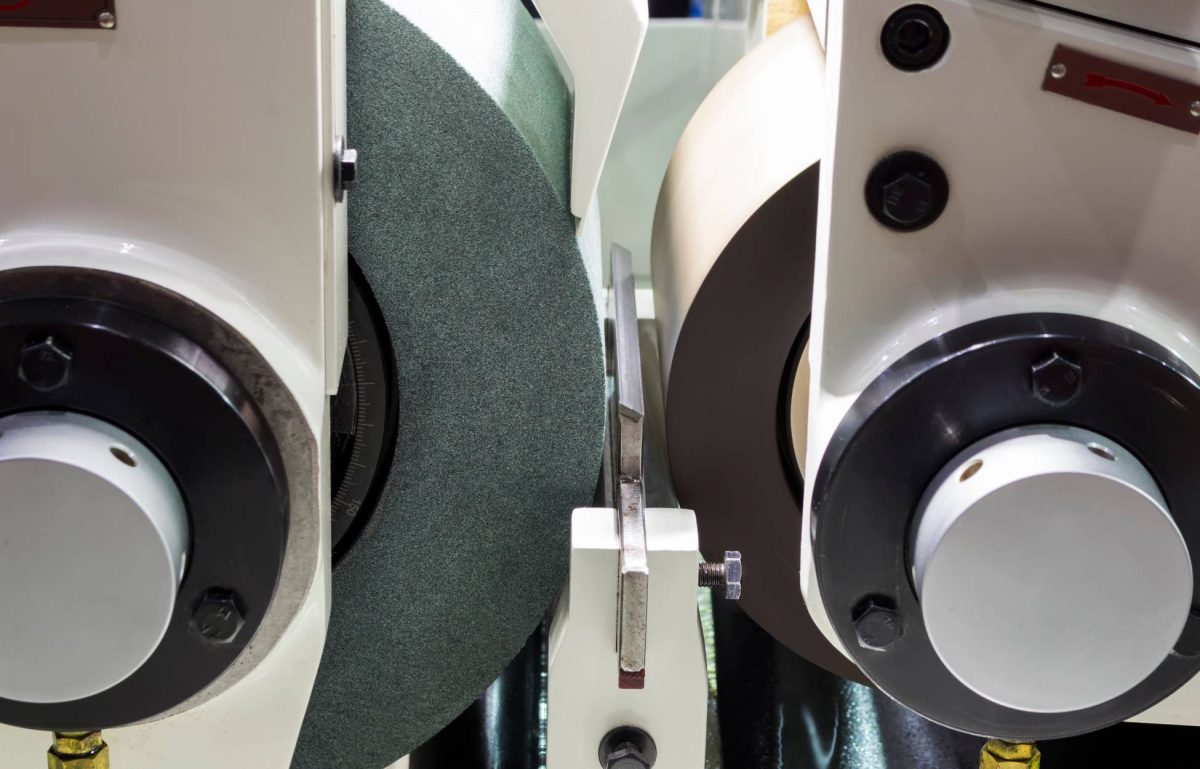

The heart of any centerless grinding operation is the grinding wheel. Selecting the appropriate wheel for your specific task is crucial. Factors to consider include the grain size, type, and the bond of the wheel. Each of these elements can dramatically impact the finish of the material being ground, as well as the speed at which you can work. Experimenting with different wheels and keeping detailed records of their effects on different materials can help you make more informed choices in the future.

Manage Your Feeding Rates

Controlling the feeding rate is essential for achieving high precision in centerless grinding. Feeding the workpiece into the grinding machine at the right speed ensures that the material removes at the optimal rate, avoiding defects like burns or undercuts. Furthermore, a well-managed feed rate enables you to achieve a consistent finish across the entirety of the material being ground, which is essential for both aesthetics and functionality of the final product.

Regular Equipment Maintenance

Lastly, regular equipment maintenance is so important. Centerless grinding machines are complex pieces of machinery that require fine-tuning of components to operate at their best. Regularly checking and adjusting the alignment, lubrication, and part replacements as needed extends the life of your equipment and ensures that grinding operations run smoothly and efficiently, resulting in higher precision and lower costs.

Implementing these tips for precision and efficiency in centerless grinding can significantly elevate the quality of your grinding projects. The key to mastering this process lies in the details, and paying attention to these can make all the difference in your work.