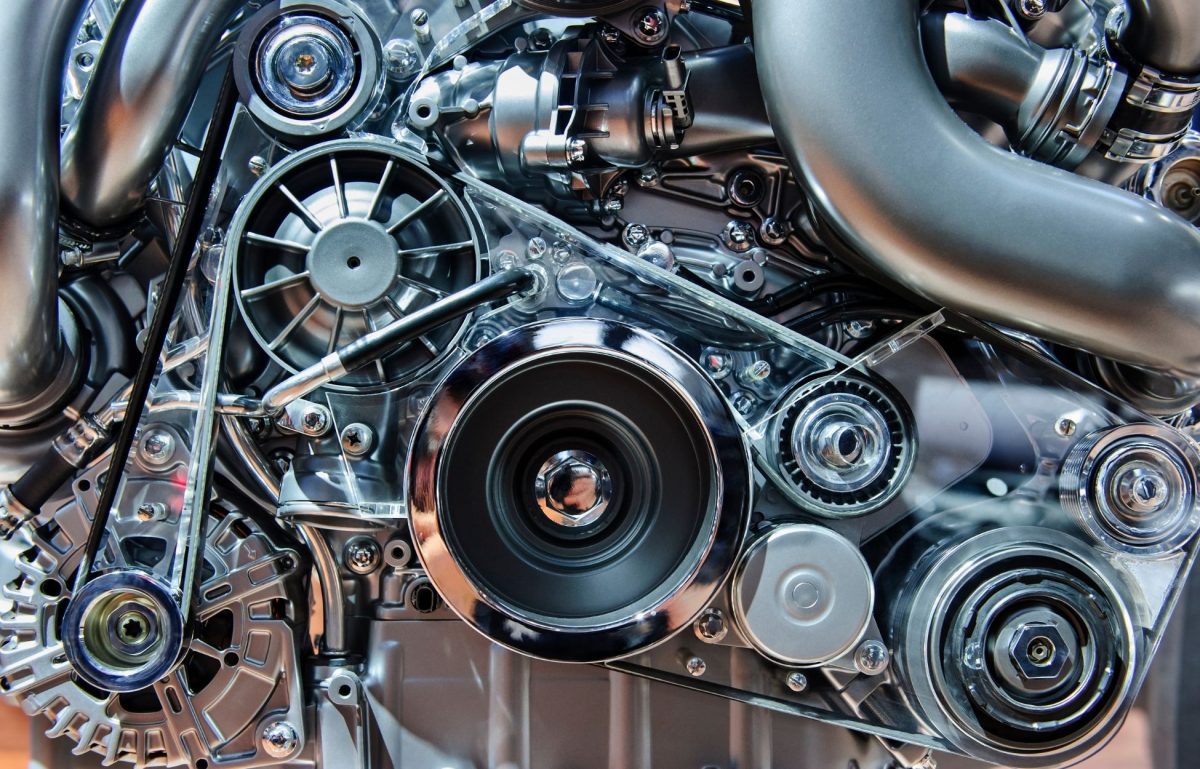

Any machine needs to have a powerful motor to perform heavy-duty tasks. The final drive motor is the primary element that allows large vehicles, such as excavators, to move around by turning the tracks. These motors need proper maintenance to keep the machines moving and perform their excavation and construction work.

Check the Oil

Final drive motors use a particular type of oil called gear oil. This oil is used in different motors that require a lot of turning gears or those with planetary systems due to its thicker consistency. The thickness of gear oil is excellent for final drive motors since long-lasting lubrication is necessary for a motor in heavy machinery that needs a motor that will work hard.

It’s essential to check this oil to ensure the final drive motor is properly maintained. Change the oil out at least once a year so the machines that the final drive powers won’t have any decline in functionality.

Inspect the Motor for Leaks

The motor is like any other part of a vehicle or machine that holds fluids, so leaks are a potential problem. A final drive motor has two sides: the hydraulic side and the planetary side. The hydraulic side includes the pump that provides hydraulic fluid to the travel motor, which converts the liquid into energy to create torque so the final drive motor will turn.

The planetary side uses a single gear called the sun gear to move smaller gears known as planet gears that cause the final drive motor to spin; this is also where the gear oil is stored. These two sides may leak gear oil or hydraulic fluid; if either depletes, the final drive motor won’t function, and the machine will power down.

Make Sure There Is Enough Lubrication

Given that so many gears are in motion that grinds against each other inside the final drive motor, it is essential to have plenty of lubrication around the gears. If the gears aren’t lubricated, they will receive damage from the constant collisions against each other, especially while the engine is idle. For the sake of proper maintenance in the final drive motor, it is essential to use gear oil as a lubricant due to its cooling properties and a protective coating.

The use of final drive motors is important for the heavy equipment we use to build or deconstruct. These motors need proper maintenance to work, so ensure you inspect them when you can to keep your machines running.