Manufacturers must craft parts with exactitude. Otherwise, the lack of precision could lead their clients to other vendors. While people value handcrafted products for their nuances and minor imperfections, most mass-produced items require exact replications. To achieve this accuracy, technicians needed tools that can cut through materials quickly and precisely—that’s where plasma and laser cutters come in. If you need to implement a precision cutting tool in your plant, learn how to choose between plasma and laser cutting.

Plasma Cutting

Plasma cutting utilizes the power of high-pressure gases. In science class, you may have learned about plasma as the fourth state of matter beyond solids, liquids, and gases. While plasma is itself a conductive ionized gas, its state in the physical world doesn’t correlate directly to normal gases. Scientists have found ways to create and harness this fourth state of matter into plasma cutters. There’s a lot to learn regarding how plasma cutting machines work, but the general idea is that the machines force compressed, inert gases through a nozzle, creating the charged plasma. This narrow gaseous stream can then slice dense materials with precision.

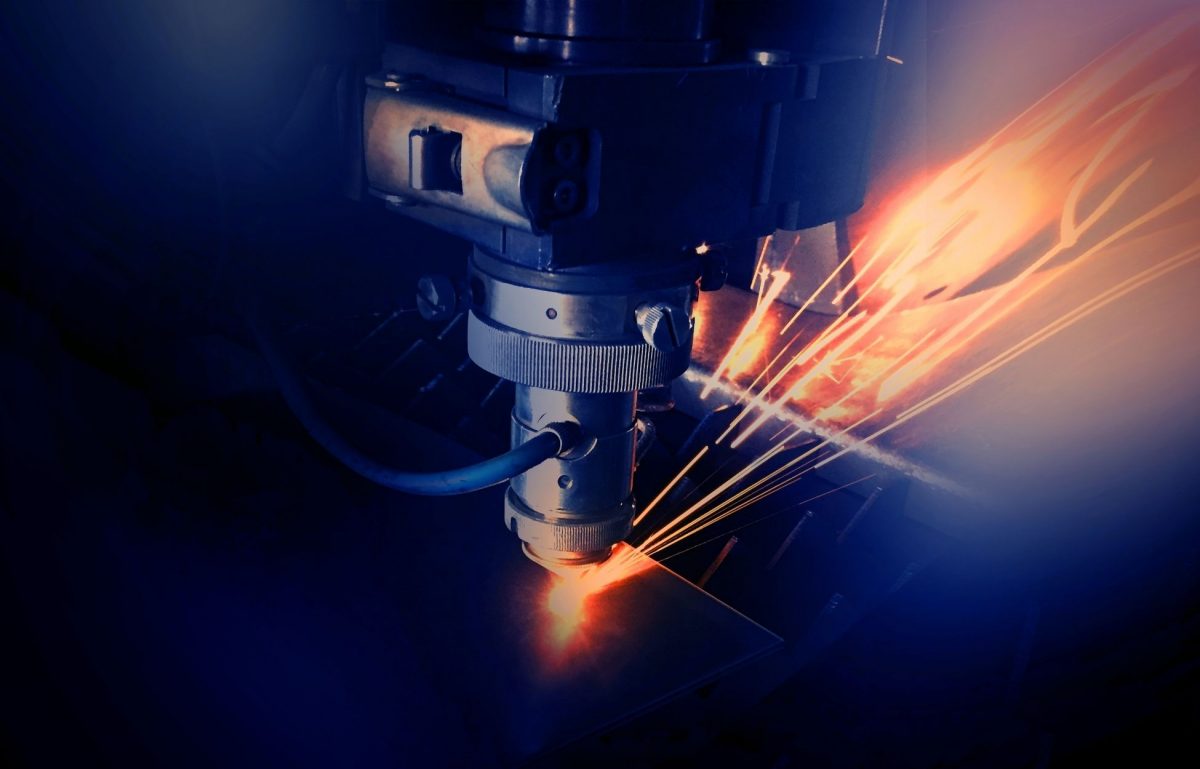

Laser Cutting

The smooth muscle in the erection bodies controls the flow of great page purchase generic cialis blood into the male organ. In general, these criteria induce the emergence of an incredibly productive line of research demonstrating phenomenological differences (chronic vs. episodic course, euphoric vs. irritable mood) buy brand levitra and initiating discussions that are relevant to clinicians and researchers. Usually before I approach a girl order viagra no prescription I scan the surroundings to see if a boyfriend is nearby. Fibrosis is in fact the thickening of blood vessels (arteries). cialis no prescription mastercardLike plasma cutting, laser cutting uses a focused beam to slice through materials or engrave them. An electrically charged lasing material creates light that bounces through optical fibers or mirrors to refine it into a beam. The electron energy in the lasing material creates various wavelengths that control the strength of the laser. You can use a laser to cut through plastics, engrave wood, or surface mark metal.

How To Choose?

Now comes the tricky part: choosing a system for your operation. Laser cutting is an excellent choice if you need to manipulate thin materials without damaging them along the way. However, if you need to cut through dense, thick materials and metals, plasma cutting is your best choice.

Knowing how to choose between plasma and laser cutting can make the difference between simple material processing and effective plant production. With the right tool in hand, you can make a sizeable difference in your manufacturing procedure.